Tungsten, known for its remarkable properties, is a metal widely used across various industries. However, it isn't utilized in its pure form due to certain practical challenges. To understand its applications and significance, let's delve into what tungsten is as a raw material, why it needs to be alloyed for machining, and the common types of tungsten alloys.

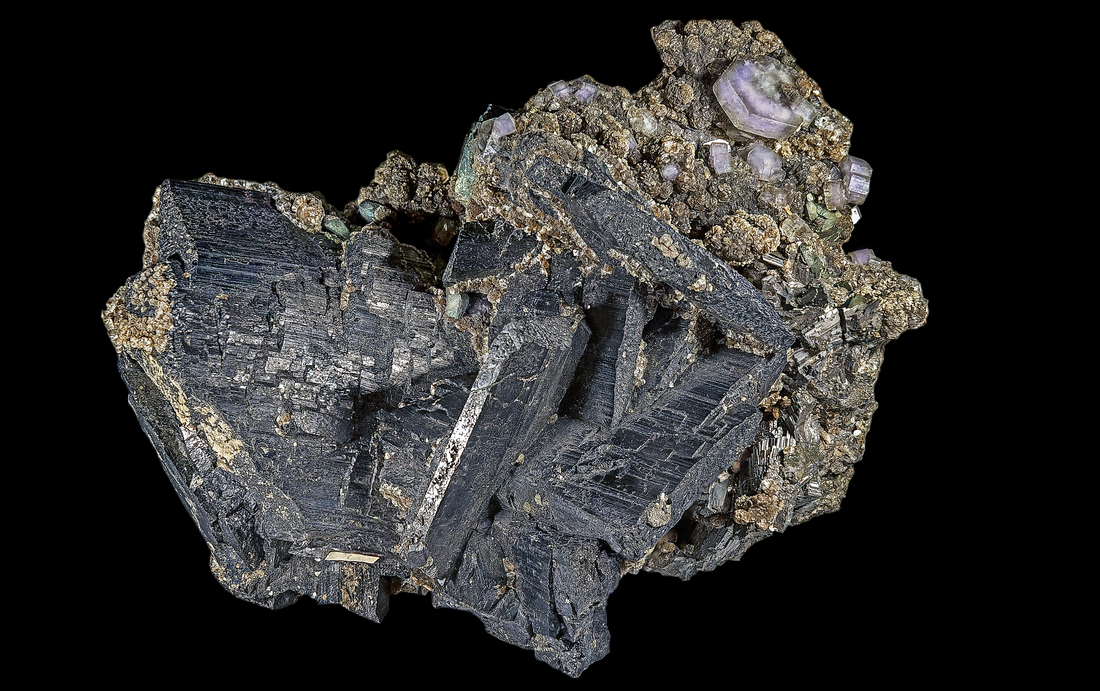

What is Tungsten as a Raw Material?

In its raw state, tungsten is brittle and hard, posing challenges for standard machining techniques. With a melting point of 3422°C (6192°F), it has the highest melting point of all metals, contributing to its remarkable thermal stability. Tungsten also has a high density, nearly 19.3 times that of water, and a hardness nearly comparable to diamonds. These properties make it ideal for applications demanding durability and resistance to extreme conditions, such as in the aerospace, military, and mining sectors.

However, these same properties that make tungsten desirable also render it difficult to process. Pure tungsten is too brittle for many practical applications, necessitating its combination with other materials to enhance its machinability and overall performance.

Image of raw wolframite, the primary ore mineral of tungsten

What is a tungsten alloy and why are alloys needed?

A tungsten alloy is a composite material created by combining tungsten with other metals, a process called alloying. This enhances tungsten's properties, making it more suitable for various industrial uses. The main purpose of alloying tungsten is to improve its machinability while preserving its high density, hardness, and resistance to heat and wear.

Pure tungsten is naturally brittle and challenging to machine due to its crystalline structure, which limits plastic deformation. When subjected to mechanical stress, pure tungsten is prone to cracking or shattering instead of bending, making it impractical for manufacturing processes that involve shaping or forming the metal.

Alloying tungsten with metals such as nickel, iron, or copper significantly reduces its brittleness and improves its ductility. These additional metals serve as binders, holding the tungsten particles together and providing the necessary flexibility for machining. Consequently, tungsten alloys retain the beneficial properties of tungsten while being much easier to work with, enabling the production of complex shapes and intricate components.

What are the Types of Tungsten Alloy Commonly Used?

Various tungsten alloys are widely used in different industries, each offering specific properties tailored to particular applications. The most common tungsten alloys include tungsten-nickel-copper and tungsten-nickel-iron.

Tungsten-Nickel-Copper Alloy

Tungsten-nickel-copper (W-Ni-Cu) alloys are valued for their excellent combination of density, strength, and ductility. Typically composed of 90-97% tungsten, with the remaining portion being nickel and copper, this non-magnetic alloy exhibits good electrical and thermal conductivity. These attributes make it suitable for applications such as electrical contacts, radiation shielding, and aerospace components.

A primary benefit of W-Ni-Cu alloys is their machinability. The inclusion of nickel and copper enhances ductility, allowing the alloy to be shaped and formed more easily than pure tungsten. Additionally, this alloy demonstrates good corrosion resistance, increasing its durability in harsh environments.

Tungsten-Nickel-Iron Alloy

Tungsten-nickel-iron (W-Ni-Fe) alloys are favored for applications requiring high strength and magnetic properties. These alloys also typically consist of 90-97% tungsten, with nickel and iron making up the remainder. The presence of iron imparts magnetic properties, making this alloy useful in applications such as counterweights, ballast, and military ordnance.

W-Ni-Fe alloys are known for their high tensile strength and toughness, enabling them to withstand significant mechanical stress. This makes them ideal for defense, aerospace, and heavy machinery applications. Like W-Ni-Cu alloys, the nickel content in W-Ni-Fe alloys improves their machinability and ductility.

Pot of molten iron, one of the components in W-Ni-Fe

Differences between W-Ni-Cu and W-Ni-Fe Alloys

The main differences between W-Ni-Cu and W-Ni-Fe alloys lie in their magnetic properties and specific applications. W-Ni-Cu alloys are non-magnetic, making them suitable for uses where magnetic interference is undesirable, such as in medical and electronic devices. Conversely, W-Ni-Fe alloys are magnetic, which is advantageous for applications needing magnetic properties, like certain military and aerospace components.

Additionally, W-Ni-Fe alloys generally exhibit higher strength and toughness compared to W-Ni-Cu alloys, making them more suitable for demanding structural applications. However, W-Ni-Cu alloys offer better corrosion resistance and easier machinability, making them preferable for components exposed to harsh environments.

Is it possible to have a 100% pure tungsten cube?

If you see a tungsten cube advertised as "pure 100% tungsten cube" this is almost certainly not correct. Tungsten is incredibly difficult to manufacture, the higher the % of tungsten, the more difficult it becomes to work with. We are yet to see a tungsten cube that has a higher percentage of tungsten than 97%.

3 inch tungsten cube from Atomic Cubes, 97% tungsten density

What are Atomic Cubes tungsten made of?

Atomic cubes are produced in a specialized tungsten metal work factory using 97% tungsten and 3% copper and nickel (97WNiCu)

We are proud that Atomic Cubes use the highest density tungsten available on the market today. For reference, our largest US competitor uses a 95% tungsten alloy, also containing 3.5% nickel and 1.5% iron.

It is important to note that the materials we use and those used by competitors look and feel nearly identical to the human eye. The weight will also be incredibly similar.

Conclusion

In its raw form, tungsten is a remarkable yet challenging metal to work with. Alloying it with other metals significantly enhances its machinability, allowing for its use in a broad range of industrial applications. Understanding the different types of tungsten alloys and their unique properties enables the selection of the most suitable material for specific needs, ensuring optimal performance and longevity.

At Atomic Cubes, we choose to manufacture using the highest possible tungsten density to give our customers the best quality.